Consultation

Competent and goal oriented.

We offer comprehensive consulting services for design, development and construction. Our consultations are based on the latest developments in the field of plastics and process technology and include a reliable calculation of project costs, as well as the selection of the most economical and functional materials.

- Start-to-finish service

- Support throughout the entire conception phase

- Selection of functional materials

- Identification of the most economical process steps

- Reliable estimation of project costs

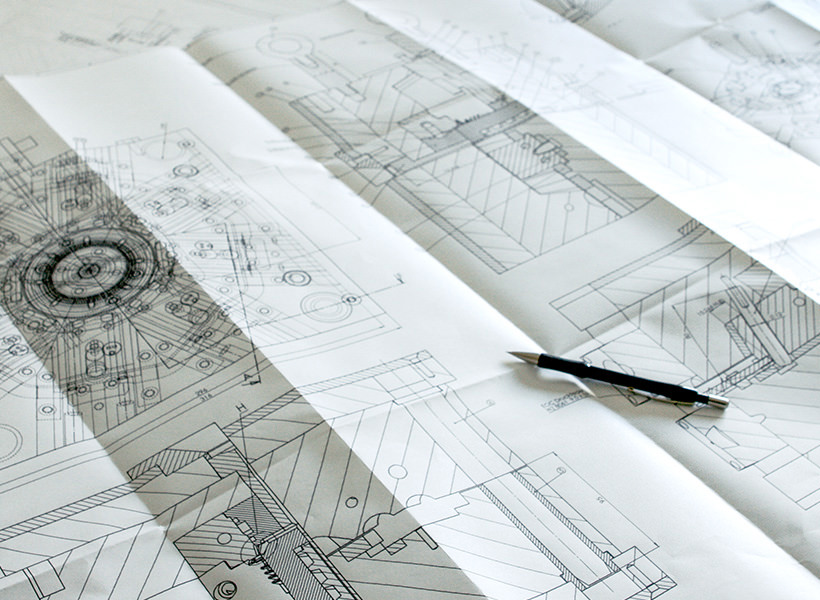

Development & Construction

From idea to marketable, high-quality product.

We create innovative products through close teamwork. Together, we will determine the exact specifications for your functional parts and components. Using simulations and prototypes, we consistently identify the best solutions and offer transparent production processes.

- Simulations

- Prototyping

- Systems: 3D CAD und CAM Systems (Solidworks, Solidcam, Mastercam)

- Interface Formats: stp, IGES, DXF, STL, Parasolid

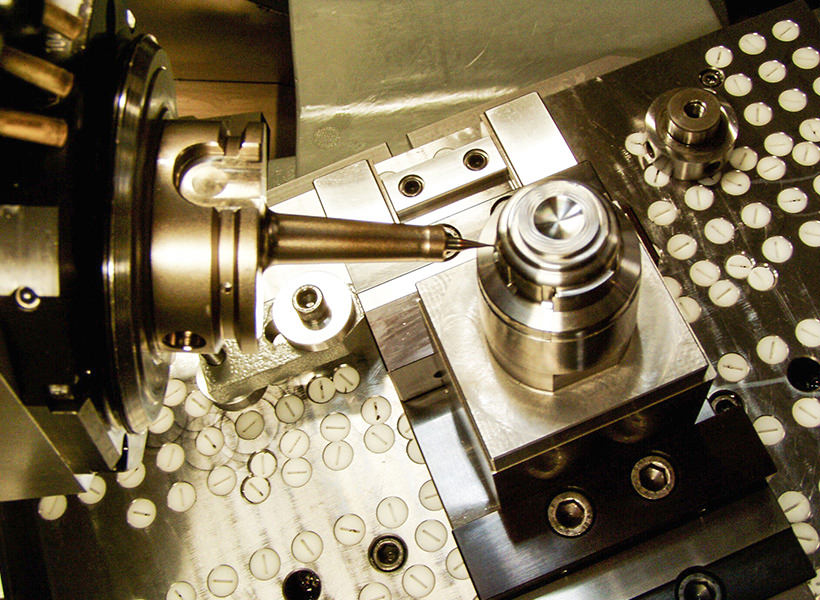

Mold Making

High-quality products cast in the same mold.

At our company, construction data is cast directly into mold making and processed by state-of-the-art CNC machines. Our highly skilled toolmakers and precision mechanists create injection molds that guarantee the highest possible product quality, as well as high production volumes.

- CAD / CAM System

- Continuous CNC Technologies

- Molds of all shapes and sizes

- Mold maintenance

- Assembly and test machines

- Prototyping

- Specialized know-how

- Fasteners

- Connector housings

- Inserts / Insert molding

- Drill-finishing molds

- Thin-wall housings

- Tools for in-mold decoration

Plastics Injection Molding

Precision meets functionality and quality.

We manufacture high-quality plastic parts of all thermoplastics. Our highly qualified process technicians utilize state-of-the-art injection molding machines and the latest processing systems to consistently ensure economical processes and the timely delivery of your product.

- State-of-the-art injection molding machines (clamp force 250kN – 5.000kN)

- Shot weight under 1g – 1500g

- Processing of all thermoplastics (except PVC), particularly engineering plastics (PC, PBT, POM, PA66, PA46, PA12) and high-performance thermoplastics (PPS, PEI, PEEK)

- Handling systems

- High degree of automation

- Specialized know-how:

- Insert molding (e.g. connectors and sheet metal parts)

- Production of visible parts (e.g. displays and interior equipment for the automotive industry)

Further Processing

Modules assembled to a tee.

Our job doesn’t end with a finished plastic part, but extends to include the professional assembly of individual modules. At the same time, we work ergonomically, thus ensuring the shortest possible assembly time.

- Handling of purchased and in-house parts

- Gluing

- Joining

- Ultrasonic welding

- Packaging

A strong impression in every last detail.

We shape your plastic parts with both functionality and aesthetics in mind and are able to precisely and neatly decorate or imprint nearly every plastic part using various printing methods.

- Pad printing

- Silk-screen printing

- Evaporation & chrome plating

- Painting

In-House Products

SNAPY – The friendly insect catcher.

With Snapy, you can carefully capture insects before returning them unharmed to the wild. Following the principle of “catch and release”, Snapy offers you a responsible and ingenious way of dealing with insects in your home by gently and safely transporting them back outside. Fly swatters and poisonous bug sprays are now obsolete, because with Snapy you can solve the problem more easily, more hygienically and – most importantly – in an environmentally friendly way.